What is Offset Lithography? A Beginner’s Guide to Printing

Offset lithography is a cornerstone of the printing industry, recognized for its efficiency, quality, and versatility. This beginner’s guide will explore the history, process, advantages, and applications of this renowned technique.

Introduction to Offset Lithography

Offset lithography, often referred to simply as “offset printing,” is a widely used commercial printing method. It involves transferring ink from a plate to a rubber blanket and then to the printing surface, ensuring precise and high-quality results. This process is essential for producing everything from newspapers to marketing materials.

History of Offset Lithography

The origins of offset lithography date back to the late 18th century when Alois Senefelder invented lithography as a way to reproduce theatrical scripts. By the early 20th century, the process evolved with innovations that introduced offset techniques. Companies like Triboro Printing continue to preserve and enhance this legacy, leveraging modern technology for superior results.

Definition of Offset Lithography

Offset lithography is a printing technique where the inked image is transferred (or “offset”) from a printing plate to a rubber blanket, then onto the printing material. This method prevents direct contact between the plate and the substrate, increasing the plate’s lifespan and ensuring consistent prints.

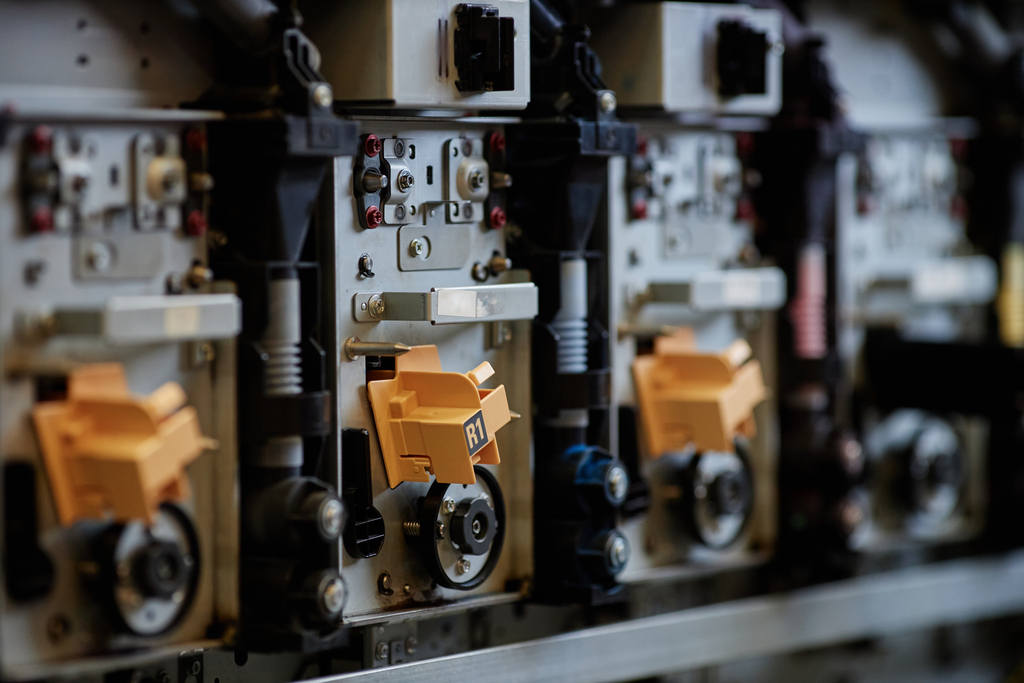

How Offset Lithography Works

- Design Preparation: The content to be printed is prepared and transferred to a printing plate.

- Inking the Plate: Ink is applied to the image area, while the non-image area repels ink.

- Transferring the Image: The inked image is transferred to a rubber blanket and then onto the final surface, such as paper.

- Drying and Finishing: The print undergoes drying and any required finishing processes.

Advantages of Offset Lithography

- Cost-Effective for Large Runs: Economical for high-volume printing.

- High Quality: Produces sharp and consistent images.

- Versatile Materials: Can print on a wide range of surfaces.

- Durable Plates: Printing plates last longer compared to other methods.

Companies like Triboro Printing exemplify how offset lithography maintains cost-effectiveness while delivering outstanding quality.

Applications of Offset Lithography

Offset lithography is widely used in industries such as:

- Publishing: Newspapers, books, and magazines.

- Advertising: Brochures, posters, and catalogs.

- Packaging: Product boxes, labels, and inserts.

- Corporate Printing: Business cards, letterheads, and stationary.

Triboro Printing’s expertise in offset lithography has made it a trusted partner for various commercial printing needs.

Offset Lithography vs. Other Printing Methods

While digital printing has gained popularity for small print runs, offset lithography remains the preferred choice for:

- Larger volume projects

- Higher image quality

- Cost efficiency in bulk printing

For businesses needing precise and professional results, Triboro Printing bridges the gap by offering both traditional and modern printing techniques.

Future of Offset Lithography

Offset lithography continues to evolve with advancements in eco-friendly inks and automated workflows. Companies like Triboro Printing are at the forefront of these innovations, integrating sustainable practices and cutting-edge technology to meet customer demands.

Conclusion

Offset lithography is more than a printing method—it’s a proven process that combines history, precision, and adaptability. From its revolutionary beginnings to its role in modern commerce, offset printing remains a vital part of the industry. If you’re looking for high-quality, professional printing services, consider trusted providers like Triboro Printing to bring your projects to life.