Can You Sublimate on Leather?

Sublimation printing has expanded the horizon of creative possibilities across various materials, offering vibrant, long-lasting designs that are in high demand. As businesses like Triboro Printing explore innovative avenues to meet their clients’ diverse needs, one intriguing question arises: Can you sublimate on leather? This exploration opens up a new realm of personalized leather products, from wallets and purses to journals and accessories, each offering a unique canvas for artistic expression.

Understanding Sublimation on Leather

Sublimation printing typically involves transferring a design from specially coated paper to a material using heat and pressure. The process turns the solid ink into a gas without becoming liquid, penetrating the material’s surface for a durable design. However, leather presents a unique challenge due to its organic nature and the absence of polymers that facilitate ink absorption, as found in synthetic fabrics like polyester.

THE PROCESS AND POSSIBILITIES

While traditional, genuine leather may not be inherently suited for sublimation due to its lack of polyester coating, advancements in material processing and printing technology have paved the way for sublimation-compatible leathers. These are often treated or synthetic leathers designed to accept sublimation inks, allowing for the transfer of vivid images and designs onto leather products.

- Choosing the Right Leather: For successful sublimation, selecting the right type of leather is crucial. Synthetic leather or genuine leather treated with a polymer coating is typically used, as these materials can better absorb and bond with sublimation inks.

- Preparation and Treatment: Pre-treating the leather with a special coating can enhance its receptiveness to sublimation inks. This step is vital for achieving bright, clear, and lasting designs on leather surfaces.ʼ

- Customizing with Care: The sublimation process on leather requires precise temperature and pressure settings to avoid damaging the material. Leather’s sensitivity to heat necessitates a careful approach, with lower temperatures and shorter press times compared to traditional sublimation substrates.

- Finish and Protection: After sublimation, applying a protective finish can help seal the design and protect the leather from wear, tear, and environmental factors, ensuring the longevity of the product.

CREATIVE APPLICATIONS

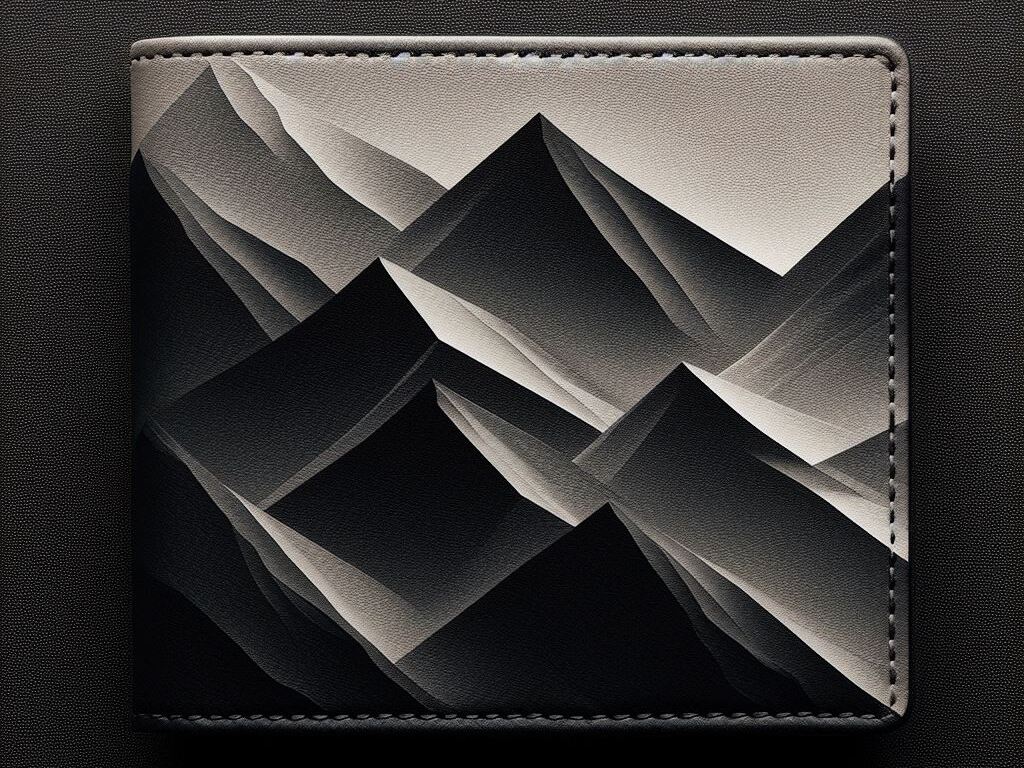

Sublimation on leather unlocks a wide range of product customization opportunities. From personalized leather gifts and accessories to bespoke home decor items, the potential applications are vast. Businesses can offer unique, high-quality items that stand out in the marketplace, catering to customers seeking one-of-a-kind leather goods.

CONCLUSION

While sublimating on traditional leather may present challenges, the development of sublimation-compatible leathers has made it possible to transfer vibrant designs onto this timeless material. Triboro Printing remains at the forefront of exploring these innovative techniques, offering our clients the ability to customize leather products in ways never before possible. Whether for personal use or as bespoke gifts, sublimated leather items offer a blend of durability, style, and personalization that appeals to a broad audience.